What Printing Services does NYES Provide?

At the New York Embroidery Studio (NYES), we provide over 80 different types of services to ensure we can meet all the needs that are requested by our clients. Specifically, our printing services have a wide range of techniques that allow us to create designs with no limitations!

Our printing services includes DTG, Flocking, Foil, Framis, Gel/Resin, Glitter, Hotfix, Reflective, Rubber, Sublimation, UV Printing, Vinyl and 3D Printing. This blog is made to teach you about each printing technique and how it can be applied to different materials to make the perfect fashion design.

DIrect-to-garment

Direct-to-garment (DTG) printing is a printing process that sprays water-based inks onto apparel using modified inkjet technology. Since DTG printers use water-based ink, you can get the best results with natural fabrics. This is because they can absorb ink very well, creating vivid colors printed directly onto the garment.

These are the most suitable textiles for DTG:

Cotton

Ring-spun cotton

Combed and ring-spun cotton

Organic cotton

Linen, other natural textiles

DTG prints stand out for their exceptional quality, delivering high-detail images and an extensive color range. This technique excels in reproducing intricate color schemes across the entire spectrum, yielding prints of exceptional detail and quality. Moreover, it embraces environmental sustainability. Thanks to advancements in technology, DTG now utilizes eco-friendly inks and operates with high energy efficiency.

flocking

Flocking is a printing process in which short fibers of rayon, cotton, wool, or another natural or synthetic material are applied to an adhesive-coated surface, adding a velvet or suede-like texture to the surface.

Flock printing is also incredibly versatile when it comes to substrate materials. Therefore, designers can use the process for toys, paper designs, plastic, and a range of fabrics. As a result, this style persisted for several decades and proliferated across various industries, including visual arts and greeting card design. Car designers even use flocking to soundproof the interior of a car. This adaptable technique serves as an alternative lining, providing a tailored fabric surface. Moreover, the texture can enhance various tools and equipment by reducing friction, preventing slipping, or increasing comfort levels.

foil

Foil printing is a method that creates metallic patterns, symbols, images, and words on a variety of fabric and leather surfaces. This procedure includes applying a layer of foil to the appropriate material, creating a dazzling metallic look.

Foil printing entails transferring a design onto specialized foil paper, also referred to as stamping foil paper, using specialized inks or adhesives.The foil paper is then carefully applied to the cloth or leather surface and pressed with a hot steel roller or iron. The heat and pressure make the foil adhere to the material, resulting in a bright, reflective metallic surface. With a wide array of metallic colors and finishes available, including gold, silver, rose gold, holographic, and more, foil printing offers endless possibilities for customization and personalization.

framis

Framis uses specially developed thermoplastic polyurethane (TPU) tapes that are heat-bonded to cloth to provide seamless and streamlined finishes. It provides several advantages in garment production. It delivers a clean and elegant design by eliminating traditional sewing methods and seams, reducing bulkiness and increasing comfort. Heat-bonded tapes form strong and permanent bindings between fabric components, assuring longevity and resilience to wear and tear.

gel/resin

Patterns and designs can adorn an array of surfaces through the process of transferring images using specialized gel or resin mediums, along with pigments or inks.

Gel dispensing printing is one example of a technology that employs resin-based gel and does not require the item to be heated or melted during the extrusion process. The most advanced UV curable gel, such as Dimengel, is completely removed from the dispenser using other types and then pushed out of the nozzle. Nevertheless, the UV-curable gel flows through different layers of the dispensing unit, with its viscosity adjusting depending on adhesion and bonding needs. UV LEDs are installed around the dispensing head to cure the gel rapidly. This ultimately decreases the need for infill to support the restructure while producing extremely durable prints.

glitter

Glitter printing is a technique that adds a touch of sparkle and glamor to printed designs. Using a heat transfer process, glitter heat prints are created by applying a layer of heat-activated adhesive to the fabric and then pressing a sheet of glitter-infused vinyl onto the adhesive. The heat and pressure ensure secure adhesion, resulting in a vibrant and reflective glitter effect

With numerous advantages, glitter print is one of the best choices you can make as it adds sparkle to the fabric. This printing technique seamlessly adapts to fabrics of any hue, boasting resilience against high temperatures and strong pH solvents. Ideal for fashion and party attire, it enhances the allure of garments with its shimmering charm.

hotfix

Hot fix is a method of utilizing robotic crystal printers that are able to place stones with exact precision. If your design is very large or requires many sizes or colors we can hand place your motifs and then permanently heat fuse them to your fabrication.

We work with renowned vendors like Swarovski and Preciosa to source top-quality crystals. We can also utilize pearls, nail heads, and novelty hot fix elements. Our comprehensive material collection presents a diverse array of choices for you to discover and customize.

Theophilio SS23

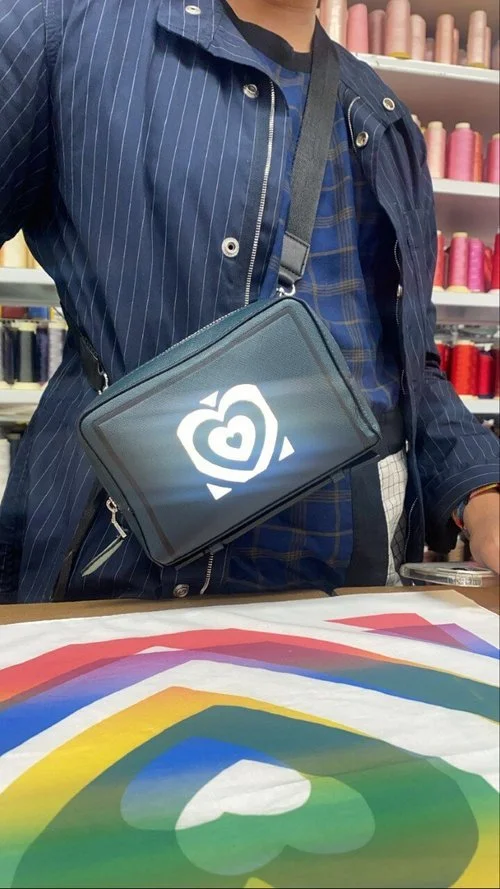

reflective

Reflective printing is a process that uses specialist vinyl and heat transfer to produce patterns with a reflecting appearance. This approach enables the creation of captivating designs that not only highlight artwork but also improve visibility in low-light settings.

After the artwork is printed on reflective vinyl, it is meticulously heat pressed into a variety of textiles, including t-shirts, bandanas, and purses. The heat treatment guarantees that the reflective vinyl attaches securely to the cloth, resulting in a strong and long-lasting pattern.

rubber

The rubber printing technique employs a unique chemical gel that combines perfectly with the dye. The dye adheres solidly to the fabric through the gel medium, bypassing the limits of water printing.

This method stands out for its ability to print with a diverse range of colors and materials. It can be applied to fabrics crafted from cotton, hemp, viscose, polyester, nylon, polypropylene, and various other fibers. Moreover, it is compatible with materials like leather, faux leather, and others. This printing technique finds application in fluorescent printing, inkjet printing, burnout printing, electrostatic flock printing, and more.

The most significant advantage of the rubber printing process is its widespread use, exquisite color, and high degree of reduction.

sublimation

Sublimation printing is a computer-aided technology for printing on polyester and other synthetic materials. It works incredibly well for printing larger yardages and personalized positioning prints. Our substantial format inkjet printers, which use specially formulated inks, can print fabrics without wasting dye or water because the inks are only printed when the pattern itself.

The technique is similar to getting a tattoo, however it is for your selected product rather than your skin. The heat opens up the fabric's pores, and with the applied pressure, the ink cools and solidifies.

The end result is a permanent, full-color image that will not break, peel, or wash away from the substrate. The method permits the ink to transition from a solid to a gas without becoming a liquid, similar to dry ice. Heat initiates the conversion, which is then controlled by pressure.

Wille Herself for Outlier IDEAS 7 Collection

Photo Credits: Zak Krevitt

uv printing

UV printing is particularly excellent for printing on hard surfaces such as leather, plastic, acrylic, and glass. Traditional digital printing can only be used on soft materials like paper and fabric. The ultraviolet printing process has transformed the printing industry. In UV printing, mercury/quartz or LED lamps are used for curing rather than heat, and they dry the inks instantaneously, releasing no hazardous fumes into the environment. UV printing outperforms normal printing on hard surfaces due to its high gloss finish, superior scratch, solvent, hardness resistance, greater flexibility, and increased strength.

vinyl

Vinyl printing is a means of applying graphics to a variety of surfaces. This method entails cutting the required design out of colored vinyl sheets and then heat pressing it onto the specified surface, resulting in a long-lasting and durable finish. Vinyl printing provides a diverse choice of colors, finishes, and effects, such as glitter or metallic, allowing for unlimited creative possibilities.

Vinyl printing uses durable, waterproof, scratch-resistant inks, making it ideal for creating a wide range of indoor and external signage. Vinyl materials can withstand anything from heat and sunlight to cold and damp conditions, making them an efficient investment.

3d printing

3D printing, also known as additive manufacturing, is a technology that creates geometric shapes by layering materials together. In the textile sector, 3D printing is utilized to manufacture prototypes of footwear, fabric, and clothing. The process of 3D printing entails applying material directly to the textile using images based on a digital design. This method ensures precise material utilization, minimizing waste and offering a sustainable alternative to traditional methods.

After familiarizing yourself with our range of printing services catering to our clients' needs, you're welcome to kickstart a project with us, bringing your ideas to life. Experience firsthand the transformative effect our services have on your attire. As the fashion industry increasingly embraces printing trends, visit our studio and delve into our swatch room to discover why our clients find these services so appealing.

references

https://arrow-digital.com/benefits-of-gel-based-3d-printing/

https://www.ankitaprinters.com/screen-textile-printing/glitter-print.html

https://www.wevolver.com/article/3d-print-rubber

https://top3dshop.com/blog/rubber-3d-printing-guide